Benchmark Technologies

Blk 1 Thomson Road #03-328D

Singapore 300001

Tel: 62568084 Fax: 62564384

email: sales@benchmark-technologies.com.sg

|

Shear Cell and Wall Friction Kits can be attached to the FT4 to determine shear properties of a

powder, including Unconfined Yield Strength and Flow Function, and the Wall Friction Angle

associated with a given material of constructions (in accordance with ASTM D7891). Shear and

wall friction properties can be used to determine critical hopper geometries using the Hopper

Design function of the FT4 Data Analysis software.

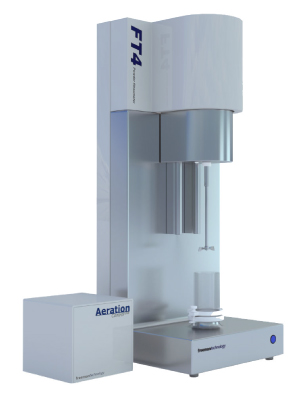

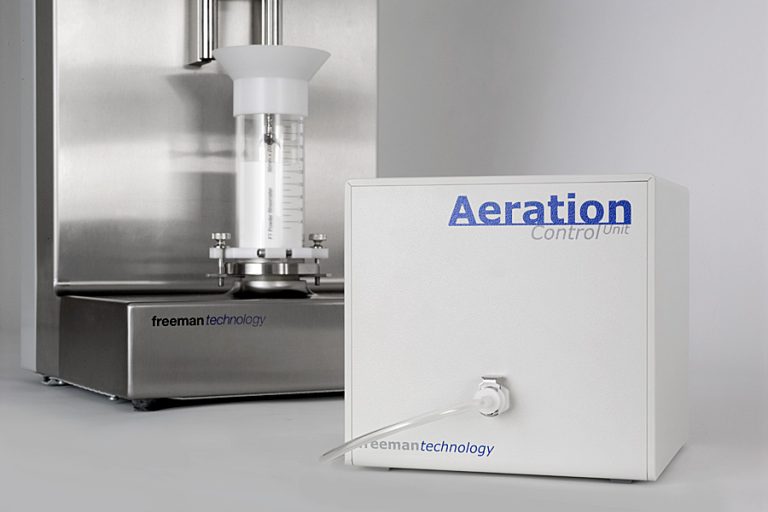

The Aeration Control Unit provides an accurately controlled flow of air to the base of the

vessel containing the powder. The unit is fully automated and software controlled,

capable of delivering a wide air velocity range, ensuring suitability for a diverse range of

materials.

25mm, 50mm and 62mm vessel kits to suit the materials being evaluated, plus a 1ml Shear Cell kit for testing scarce, valuable or hazardous powders.

The FT4 measures the resistance that a powder exerts on twisted blade, as it forces

its way through the sample. This resistance is expressed as “Flow Energy”, calculated

from direct measurements of torque and force.

The vented piston is used to be apply a consolidating stress to a powder sample to quantify properties such as Compressibility and Permeability in order to understand the effects of storage and handling.

The Compact Hardness and Compact Payoff accessories can be used to evaluate the quality

of cosmetic powder compacts. Both accessories can be used with three sizes of compact

and utilize a novel vacuum base removing the need for complex and intrusive mechanical

fixings.